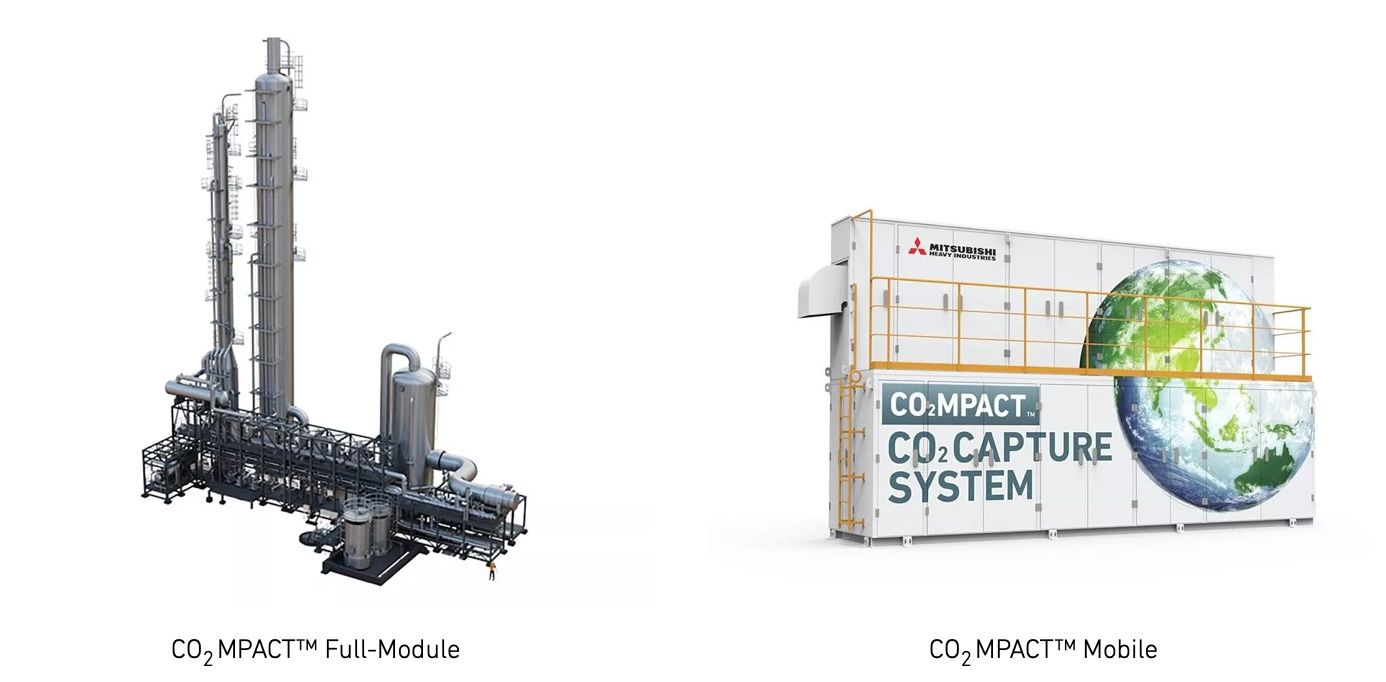

Renewal of Compact CO2 Capture System "CO2MPACT(TM)" Series

TOKYO, Sept 19, 2024 - (JCN Newswire) - Mitsubishi Heavy Industries, Ltd. (MHI) has renewed CO2MPACT™ series, which has been commercialized for decarbonization of a wide range of industries. The new model adopts a mass-produced full-module concept based on standard design as a middle size of CO2MPACT™. By maximizing the module ratio, it is possible to improve the efficiency of on-site fieldwork and shorten the construction period, which occupies a large volume of conventional plants delivery time.

The new model, "CO2MPACT™ Full-Module," will be able to propose the optimum capacity of captured CO2 according to the flue gas from customer's facility in the range of 1 to 200 tons/day. In addition, more than 90% of the equipment is modularized into the container size or prefabricated in a workshop. As a result, the work volume at construction site will be greatly reduced, especially the on-site welding work, by 95%. CO2MPACT™ Full-Module inherits its development concepts such as "easiness," "lightness," "moving fast," and "simple,". Going forward, MHI Group will further strengthen the customer support package, encompassing everything from initial planning to after-sales servicing, through the lineup with "CO2MPACT™ Mobile," which has already been delivered for demonstration tests in various industrial fields.

MHI Group will also exhibit at CCUS WORLD, the first large-scale carbon dioxide capture, utilization and storage (CCUS) exhibition in Japan, to be held from Wednesday, October 2 to Friday, October 4, at Makuhari Messe, Chiba, and introduce the concept of the CO2MPACT™ series and CCUS value chain, one of the Group's future growth areas, by using digital materials. In the exhibition, on Wednesday, October 2, Tatsuto Nagayasu, Senior Vice President (CCUS) of GX (Green Transformation) Solutions, will give a keynote speech on "CCUS Growth Strategy of Mitsubishi Heavy Industries Medium-Term Business Plan."

MHI Group has formally declared its intent to achieve carbon neutrality by 2040, and the Company is now working strategically to decarbonize both the energy demand and supply sides. A core element of the Company's "Energy Transition," which targets decarbonization on the energy supply side, is the development of a CCUS value chain integrating diverse sources of carbon emissions with modes for carbon storage and utilization. Going forward, MHI Group will continue to proactively promote its CCUS business worldwide, applying its proprietary CO2 capture technologies, contributing as a solutions provider to reducing greenhouse gas emissions on a global scale, and developing further solutions that contribute to environmental protection.

About MHI Group's CO2 capture technologies

MHI Group has been developing the KM CDR Process™ (Kansai Mitsubishi Carbon Dioxide Recovery Process) and the Advanced KM CDR Process™ in collaboration with the Kansai Electric Power Co., Inc. since 1990. As of September 2024, the Company has delivered 18 plants adopting these processes. The Advanced KM CDR Process™ adopts the KS-21™ solvent, which incorporates technological improvements over the amine-based KS-1™ and offers superior regeneration efficiency and lower deterioration than the KS-1™, and it has been verified to provide excellent energy saving performance, reduce operation costs, and result in low amine emissions.

For further information on MHI Group's CO2 capture plants: www.mhi.com/products/engineering/co2plants.html

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.